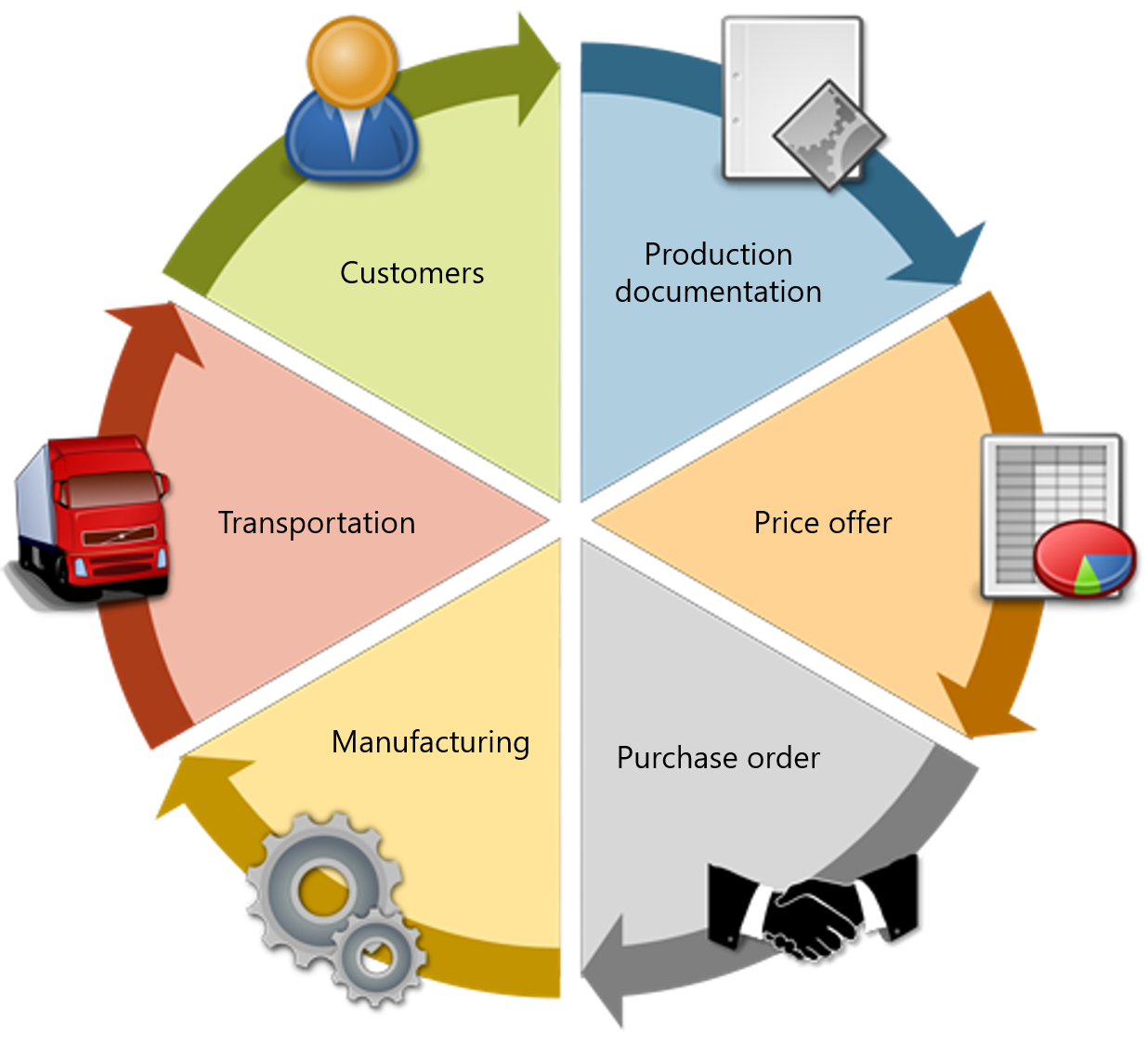

Production

Our company focused on welding, CNC and NC machining with an aim to provide complex manufacturing services of custom production with specialization on machining, welding of wagon components (lock seat creepers, platforms for immobile people, pantographs, gear mechanisms, special door lock parts) and mechanical assembled units for agricultural, automotive and handling machinery.

Manufacturing documentation

Due to our technological capabilities we can work with production and project documentation in CAD 2D and 3D formats. We can also use the traditional paper documentation.

Complex manufacturing capacity

Welding parts are welded in a protective atmosphere CO2 MIG/MAG (welding units, including pulse welding units - Fronius) and TIG/WIG. Due to the technological equipment we can manipulate and assemble units up to 3,5 t.

Wagon components production

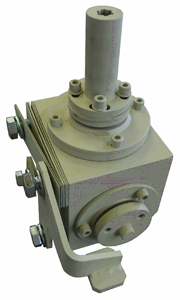

The complete production of simple transmission units for tilting of boarding grids of running boards for railway vehicles. System is composed of transmission machinery and footboard.

We also manufacture lifting mechanisms for different types of trains.

Individual mechanisms for opening and closing doors, wagon shelves, grids and different types of locks.

Design and development of special products – custom production

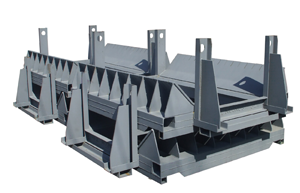

Production of large welded units including assemblies up to 3,5 t according to project documentation.

Production of beam elements for robotized workplaces.

Mechanical tipping machine of manufacturing lines, components for rolling lines of various diameters and lengths.

Productions based on custom documentation.

Production of parts for agricultural, automotive and handling machinery

Delivery of welded components and completely assembled units for agricultural, automotive and handilng machinery including surface treatments with powder coating for important European customers from Germany, Austria, Denmark, Belgium, Netherlands etc.

For more information go to ISMM Production & Business Cooperation Ltd. web.

Machinery and technological equipment

To all of our equipment were added digital read outs (DRO) made by the company LIMAT LTd., version MAXI 2 and MAXI 3, to ensure the production tolerances.